FAQ

- Do you remanufacture injectors?

- Can you just modify my nozzles and send them to me, my truck is a daily driver and I can't pull it out of service to send you the injectors?

- Is testing and balancing really necessary?

- How do you test and what does it mean to me?

- Do you sell injectors?

- Are "reman" injectors any good?

- How can I determine my pump is built by Exergy?

- How can I determine which Exergy pump I have?

- If a body is cracked the injector is bad, are there other reasons for having to replace an injector?

- Are stainless steel 5.9 injectors better than standard 5.9 injectors?

- Do you do 12 and 24 Valve mechanical Injectors?

- Do you test or repair high pressure CP3 Pumps?

- How big of an injector (or flow of nozzle) do I need?

- Do you service Ford 6.4 injectors?

- Should I install a "race valve (rail plug)" in place of my factory PRV (pressure relief valve) to get more rail pressure??

- Do I need to replace my High-Pressure cross feed tubes when I replace my Cummins injectors?

- Can I remove the injector edge filter for better flow?

- What about extra filtration?

- Can I send my unknown companies modified injectors in and have them repaired or balanced?

- My balance rates are off, what can I do?

- Do I have to enter the injector output codes or also identified as the "NIMA codes"?

- Do you modify the latest Piezo injectors for the 6.7 Ford and L5P Duramax?

Q: Do you remanufacture injectors?

Currently we do not remanufacture injectors. The time and component costs of doing the job correctly are equivalent to purchasing a new Genuine Bosch remanufactured unit. To date, they are the only ones remanufacturing them correctly.

However, we repair injectors for broken stators, damaged high-pressure fittings, worn nozzles, or a no fire condition caused by gummed up fuel or extended downtime.

Q: Can you just modify my nozzles and send them to me, my truck is a daily driver and I can't pull it out of service to send you the injectors?

As much as we would like to help, we don’t feel comfortable with sending nozzles out without our final assembly and testing. We have done thousands of injectors sets and can say that often we find an issue with a used set of injectors that requires attention. Sometimes major adjustments are needed and sometimes minor, but we correct them, if possible, at the final balance calibration.

Same goes for new and “reman” injector sets. The injectors are calibrated at Bosch to their standards as stock, but once the nozzles have been modified and re-installed onto the injectors, we often must adjust them in the final balance calibration to get them back into our specifications. When adjusting in microns even the smallest change creates a large effect.

Our suggestion is to keep running your injectors until your set needs attention. We could then work up a set of new/reman oversized injectors and send them to you. You would then install and send your old injectors back as cores. (We allow a 30-day window for core returns for full credit.)

Q: Is testing and balancing really necessary?

Look at the comments from some of the most prominent tuners and builders in the country shown on our "Why Exergy" page. The true question is can you expect top performance without it? Do you want to take the chance of a good install to find out later you have a bad injector? The top mechanical fuel system users in the country (P-Pump 12 and 24V) balance the pump and injectors as a set, i.e., equal fuel and equal timing for all cylinders. Similarly, top common rail fuel system users in the country, from truck pulling, drag racing and even competitive street trucks, rely on consistent, reputable, and balanced injector sets to stay at the top.

When we test and balance, we adjust internal assembly dimensions that may have drifted over time from their proper specifications. We measure and correct for proper operations across the operating range from idle to full power. This becomes increasingly important with higher nozzle flows.

The testing on “mild” builds is not as critical as these systems are often easier to service. Failure modes are much "softer" such as an odd noise or excessive smoke. Should something go wrong on a more “complicated” build like a common rail system, complete engine destruction could occur.

Q: How do you test and what does it mean to me?

We fully test from idle to full power using factory calibration points, and a few of our own for the high-performance market. We can fully map injector sets and have done so for several customers who want to best utilize their standalone ECU or EFI Live capabilities.

We use equipment developed and used by Bosch for the design and development of diesel fuel systems (specifically Common Rail) and have the expertise to properly operate and maintain this very sophisticated equipment. Some of our staff participated in the development of this equipment as well as Common Rail Injectors at Bosch. Our "toolbox" is very extensive, along with our knowledge base. Most of us have been in the diesel business for more than 30 years and have worked on the design and development of many types of diesel fuel systems from ships to single cylinder utility engines.

Our equipment can measure not only injection quantity and timing but shot-to-shot consistency and a number of other injection characteristics. This capability is far beyond the test equipment found in OEM service centers. We have analyzed others’ injector sets and neither timing or shot-to-shot output is being controlled, let alone measured. We also found that they made changes that brought the injectors into calibration at a few low-pressure test points (where their benches are able to operate), but in doing so the hydraulic response of the injectors to the electrical drive signal is adversely affected. We have seen the beginning and end of the injection event vary more than 3 crank degrees across a freshly "rebuilt and blueprinted" injector set.

If you choose to work with another performance supplier, ask first for a copy of a typical test summary sheet. Do they provide injector output at multiple test points? Do they test at full rated pressure and output (23,200 psi for 5.9/LB7/LLY and 26,100 psi for 6.7/ LBZ/LMM)? Do they measure injector stability? Can they provide an output vs pulse width map at various rail pressures? Can they measure injector response time to drive signal?

If we test your injectors and find them to be within factory specifications for output timing and consistency it does not always mean they are as good as new. The wear and mileage they had when they arrived is the same as when we are done testing. We cannot lessen the mileage and wear that already exists. In general, original 5.9 and LB7 injectors are worn out at 100k miles. LLY/LBZ/LMM and 6.7 injectors typically last longer and are starting to show signs of wear at 150k miles. We have tested many sets that meet specifications with over 200k miles but have also seen sets with 50k miles that do not. This is a VERY general number and depends on many factors including fuel, how well the fuel system was maintained, duty cycle and modifications.

Q: Do you sell injectors?

Yes, see our website or check with our dealers for pricing. All the injectors and pumps we modify, and sell, are originally sourced from Bosch as remanufactured or are new units from Duramax, Cummins and the new 6.7 Ford Powerstroke. We can also source most Bosch fuel system components. We just need a Bosch part number or an engine serial code to look up pricing and availability. Our prices may not be the lowest for these custom parts, and the lead times may be longer than those of a competitor, but we only sell injectors and components that are the best available. (Normal core requirements apply.)

Q: Are "reman" injectors any good?

In our opinion the only proper remanufacturing is done by Bosch and these injectors are better than the original injector design. All wear components have been replaced with new, and in most cases improved parts, making Genuine Bosch Remans an excellent value.

Q: How can I determine my pump is built by Exergy?

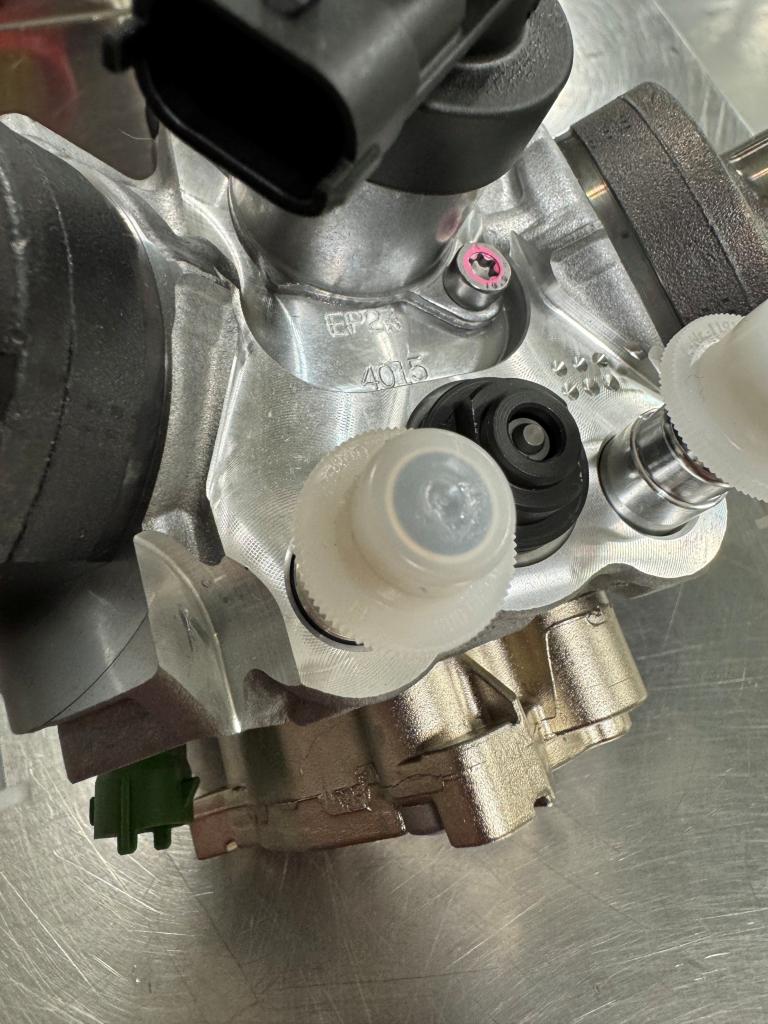

The easiest way to determine whether or not your pump was built by Exergy is to look for the "EP Number" we stamp on every pump we produce. On our CP3s, the EP Number can be found on the manifold, near the MPROP/FCA. On our CP4.2s, the EP Number is found at the top of the pump, right next to the MPROP/FCA.

CP3:

CP4.2:

Q: How can I determine which Exergy pump I have?

All pumps built by Exergy are stamped with an "EP number". The EP number can be found following the directions in the FAQ above. It should read "EPXX XXXX". Here is how you decode the EP number:

The first numbers after the EP Is the year the pump was built. The first number of the set of 4 corresponds to the size of the pump.

0- 10mm

1- 12mm

2- Sportsman

3- 14mm

4- 10mm LML CP4.2

5- 10mm Power Stroke CP4.2

7- 10mm Cummins CP4.2

9- Alpha 550

So, as an example: EP22 2005 would be a Sportsman CP3 built in 2022.

Q: If a body is cracked the injector is bad, are there other reasons for having to replace an injector?

Components in injectors wear over time, with the LB7 Duramax and 5.9 Cummins having the shortest life of all Bosch Common Rail injectors. Bosch continues to tweak the design to improve fuel control and durability. The LLY/LBZ/LMM and 6.7 injectors are the results of this labor. Under normal conditions you can expect to need injector replacement at 100k miles with the original 5.9 or LB7 series. The replacement injectors (Genuine Bosch “remans” or new) are more durable than the OEM versions but are still not as good as later model (LLY/LBZ/LMM 6.7) design iterations.

Q: Are stainless steel 5.9 injectors better than standard 5.9 injectors?

Injectors do not have stainless steel bodies. The new 5.9 series injectors have been changed to the same material used for the higher pressure rated 6.7 series injectors. The new body material of the new 5.9s is stronger but still not as good as the 6.7 injector, which was originally designed to withstand higher injection pressures, and was shinier, (looked like stainless steel). In terms of reliability and strength, this body material is an improvement over the original but not as hard as stainless.

Q: Do you do 12 and 24 Valve mechanical Injectors?

No, we do not work with mechanical diesel fuel systems. We are focused on common rail systems only and the development of the newer applications like the Chevy L5P Duramax, Ford 6.7 Powerstroke, 2019+ 6.7 Cummins, etc...

Q: Do you test or repair high pressure CP3 Pumps?

We do not test, nor repair used stock or modified high pressure pumps. Unfortunately, when running one of these used pumps on our test bench, the bench must be partially torn down and thoroughly cleaned of all possible debris and contaminants before we run our new modified pumps.

Q: How big of an injector (or flow of nozzle) do I need?

Making a set of injectors to achieve your power target as smoke-free as possible is no problem. However, specifying a set that best meets the targets for your application is best done by a dealer, especially at high power levels. There are several variables to consider, and our specialty is more in building the injectors than specifying them. The price from a dealer, or direct from us is the same, so it is best to get as much dealer application experience involved as possible. Please visit our website for a list of our dealers. We believe the experienced dealer approach to any project is the best way to maximize your performance investment dollar.

Q: Do you service Ford 6.4 injectors?

No, we do not currently work with or test 6.4 Powerstroke injectors. In 2008 - 2009 we spent several months developing test equipment and a test procedure for this injector. Throughout this time, we were unable to match the results on our test bench with those in the vehicle. In other words, the outputs/performance on bench did not match the power levels observed in the truck. After this time and effort, we decided to stop the development work. Rather than conducting further development "on the back" of the customer and risk getting a "black eye", we do not test them. We recommend you strongly question any company that can promise accurate testing of these injectors. In our opinion, if the diagnostics on the truck say it's bad, it probably is.

Q: Should I install a "race valve (rail plug)" in place of my factory PRV (pressure relief valve) to get more rail pressure??

No, we do not recommend eliminating the factory PRV in your HP fuel system. The PRV is there for a reason; to eliminate the damage that can be caused by pressure spikes. When a "race valve (rail plug)" is installed these pressure spikes have nowhere to go except into the injector. The only time plugging the rail will fix a rail pressure issue is if the factory PRV has been blown off multiple times and is starting to wear out.

At this point we suggest replacing the worn PRV with another factory unit. For higher pressure applications we can modify a new PRV to a higher blow off point so you're not on the edge of the stock factory unit while still retaining the safety function of the PRV. We have seen many injector sets returned due to rail pressure spikes causing premature wear of the internal components and stators lifted or blown off the top of the injector while running these plugs. In extreme cases rail plugs have also resulted in cracked injector bodies.

Q: Do I need to replace my High-Pressure cross feed tubes when I replace my Cummins injectors?

We re-use the same high pressure feed tube in the fixture on our test bench. However, if it leaks on our bench, it is easy to spot and fix. We are also installing and uninstalling many Cummins injectors a day and change feed tubes out on a regular basis due to wear over time.

If you do not want to change the feed tubes, at a minimum, a careful inspection of the end of the feed tube is necessary. If there is any scratch, ding, dent, or other signs of damage, you should replace them. If you suspect the system may have been contaminated with debris or water, replace them all. With the edge filter in place there is no way to be sure you have cleaned the inside of the tube and we do not recommend the removal of any edge filter.

If the edge filter is removed, there is nothing stopping a piece of debris from getting into the injector, becoming lodged in the injector control system, holding it open, and dumping as much fuel as the pump(s) can produce.

The "Official" Cummins, Bosch, and Ram recommendation is to replace all feed tubes when the injectors are removed. Some shops always replace the tubes as they have experienced leaky feed tubes. Our recommendation is to change the feed tubes when you install a new set of injectors, but the choice is yours.

Q: Can I remove the injector edge filter for better flow?

The injector output is increased slightly by removal of the edge filters, but we believe the cost of the smallest piece of debris locking the injector open is not worth this small gain in output. This holds true on all the Duramax applications and Cummins applications that use the side feed connector tubes. It's better to properly size the nozzle to hit your desired fuel level.

If the high-pressure fitting has been damaged on your LLY/LBZ/LMM injector, we can replace it with a new fitting, edge filter and properly crimp the collar in place.

Q: What about extra filtration?

Typical stock filters are rated at 5- micron and are generally sufficient for stock applications when serviced at proper intervals, but additional filtration and water separation is always recommended for even stock vehicles.

For higher output, and higher flow, staged filtration, as used extensively in the heavy-duty diesel world, is the best. A 10-micron primary filter followed by a 5, or even 2, micron secondary filter is recommended. End use and geography comes into play as well. In northern climates fuel waxing must be taken into consideration with lower micron rated filters subject to quicker plugging with gelled fuel.

As a rough guideline, the filter package should be able to flow 150 gallons per hour without generating excessive backpressure for each CP3 pump (stock or modified). This assumes each one is being fully utilized.

Q: Can I send my unknown companies modified injectors in and have them repaired or balanced?

We can baseline function test your injectors but that is as far as we can go. If they are out of balance, have nozzle or body issues, have internal debris, etc., we are unable to fix them. We do not work with, or repair, any other company’s modified products. Typically, these products do not meet our quality control standard which makes it nearly impossible for us to work with them.

Our baseline function test consists of an external cleaning of all injectors. Next, we run them on our test bench. Then we evaluate them using key factory calibration points like pilot, idle, low and midpoint quantities, as well as checking the return flow of each injector. This information gives us a really good idea of how the injectors are performing and what might be wrong with the injectors. These tests should correlate to the symptoms you are having in your vehicle. Check out the example of our calibration sheet on our service page.Q: My balance rates are off, what can I do?

GM balance rate limits with the vehicle at operating temperature are +/-4 at idle in park and +/-6 at idle in gear.

Balance rates are an indicator of how evenly each cylinder is accelerating the crankshaft. Anything that affects cylinder firing "strength" will affect the balance rate readings. We have heard of the normal reasons such as valve lash and low cylinder compression (copper seal, loose injector cup (LB7), rings, head gasket, etc...) affecting balance rates. Incorrect injector output codes or NIMA codes can throw off balance rates as well (see question #20). We have also seen unusual things such as bent connecting rods causing high balance rates. So, there are several factors besides injectors affecting balance rates, and they should be eliminated as possible contributors before removing the injectors.

To help determine if the root cause is related to the injectors, or one of the other items mentioned above, exchange the injector in the questionable cylinder with one from another cylinder. If the excessive balance rate does not follow the injector to its new position, begin checking the engine related items listed above. If the balance rate does follow the injector, the injector may need to be repaired (if possible) or replaced.

Q: Do I have to enter the injector output codes or also identified as the "NIMA codes"?

When installing a set of modified injectors in an engine that is equipped with injector output codes or NIMA codes, set all the cylinder codes to the same value. Once modified, it is likely the injector no longer has the output characteristics that are mapped in the factory NIMA code. Since Exergy has already balanced the injectors on the bench, it is best to have the ECU treat them all the same rather than try to compensate for an output characteristic (high or low) that is no longer there. Pick any one of the codes off any one of the injectors and enter that code for all in the ECU.

Q: Do you modify the latest Piezo injectors for the 6.7 Ford and L5P Duramax?

Yes, we can increase the injector output on the latest Piezo injectors. We completed our initial development testing in 2013 for these modifications and have moved forward with several injector sets to assure excellent set balance and consistency with great results. Email our sales department for the latest status.